Pellet storage in the heating room

Switching from an oil heating system to a pellet boiler is simple. The old oil boiler is removed from the heating room, and the new pellet boiler takes its place. At BRUNNER, all dimensions, connections, and controls are designed so that integration with the existing central heating system is quick and easy. The pellet storage room – usually the former oil tank room – can be set up in the basement without any major construction work.

Pellets are delivered by tanker truck and blown dust-free into the pellet tank or storage room. From there, the required amount is automatically drawn into the boiler. A sloped floor inside the storage room ensures that the pellets slide naturally toward the feed system. The slope should have an angle of about 45 degrees.

Pellet storage options: sack silos and more

There are several options, such as pellet tanks in the form of sack or fabric silos, underground tanks, or prefabricated storage units. The choice depends largely on individual requirements and the available space.

When planning a pellet heating system, proper storage is just as important as the boiler itself. It’s essential to ensure that the pellet storage area is easily accessible for a silo truck and that filling can be done cleanly and safely through a filling connector – without spills or dust.

Pellet storage options: sack silos & more

There are several options for pellet storage, such as tanks made from fabric or sack silos, underground tanks, or prefabricated storage units. The right choice depends on individual needs and local conditions. When installing a pellet heating system and storage, accessibility for delivery trucks must always be considered. In some cases, special filling systems and fittings are required.

Proper ventilation of the storage room is also crucial to prevent moisture buildup, which can cause pellets to clump or degrade in quality over time.

Where can pellets be stored?

Pellets should always be stored in dedicated rooms or containers that protect them from moisture, dirt, and environmental influences. The storage space can be located inside the house or in an adjacent building, as long as it’s connected to the exterior wall to allow proper filling and air exchange.

Sack silos are durable containers, often made of metal or plastic, providing a simple and weather-resistant storage option. They come in various sizes and can be placed near the boiler.

Fabric silos are made of flexible, heavy-duty textile materials that form a closed container supported by a stable frame. They are lightweight and easily adaptable to different room conditions.

Underground tanks (earth tanks) can hold larger quantities of pellets and are usually well insulated to regulate temperature and humidity. Installation requires professional groundwork, making them suitable for higher pellet demands.

Prefabricated storage units are insulated, ready-to-use structures specifically designed for pellet storage, available in different sizes to fit varying needs.

For small spaces, the BRUNNER weekly hopper is an ideal alternative. Holding up to 300 kg of pellets, it can be refilled manually every one to two weeks with standard 15 kg bags. The entire heating system requires only about one square meter of space.

The choice of the right storage system depends on factors such as available space, required storage volume, and local building codes. Storing pellets outdoors without proper protection is not recommended.

How big should a pellet storage be?

The ideal storage size depends on fuel consumption, heating demand, local regulations, and individual requirements.

Pellet consumption: The yearly amount of pellets determines the needed storage capacity. As a guideline: if a household previously used 1,000 liters of heating oil per year (approx. 8,000 kWh of heat), that equals roughly 2 tons of pellets.

Storage type: Depending on whether you choose a sack silo, underground tank, or prefabricated unit, space and capacity needs will vary. Underground tanks typically hold more.

Local regulations: Building and fire safety codes may limit the maximum size of the storage area, so always check regional guidelines first.

Delivery cycle: Larger storage allows for fewer, more efficient deliveries—ideally covering a full year’s demand in one fill.

Climate: In regions with severe winters or difficult delivery conditions, larger storage ensures uninterrupted heating even when access is limited.

Pellet transport systems

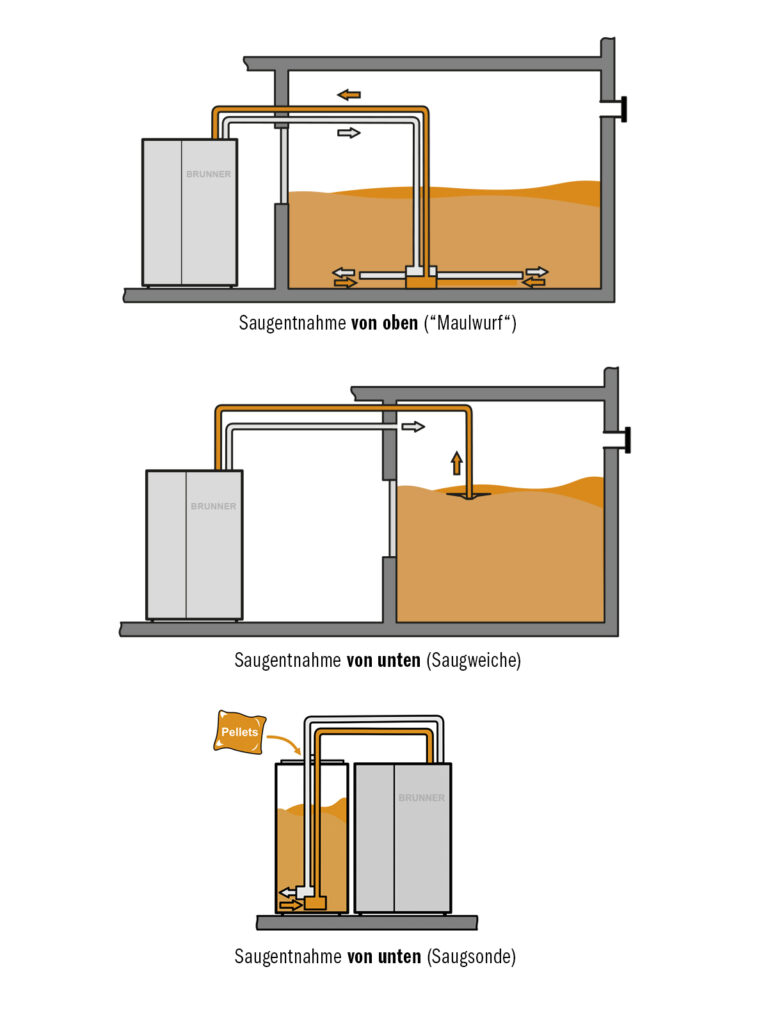

Different feed systems are used to move pellets from storage to the combustion chamber. The right system depends on the type of storage and the specific setup of the heating system.

In short, well-planned and properly maintained pellet storage ensures safe, efficient, and reliable operation – and is key to getting the most out of your BRUNNER pellet heating system.

Pellet feed systems

- Fabric silo or storage room with suction “mole”:**

In a fabric silo or storage room equipped with a suction mole, the pellets are extracted from above, ensuring efficient fuel transport to the boiler. The mole automatically moves through the entire storage area, allowing the room to be emptied completely. - Fabric silo with switching valve:**

A switching valve is a special device that controls the suction or intake of pellets from the silo, ensuring a smooth and reliable transfer of fuel. - Storage room with suction probes:**

Suction probes deliver the stored pellets to the boiler and operate together with an air-driven vacuum system. This method ensures consistent pellet transport and clean handling.

Conclusion

In summary, proper pellet storage is a key factor for the efficient and reliable operation of a pellet heating system. Choosing the right storage solution, ensuring correct filling, ventilation, and protection are all essential components that contribute to both the system’s performance and its longevity. The size of the pellet storage depends on the annual fuel requirement.