The features

- 1. Efficiency

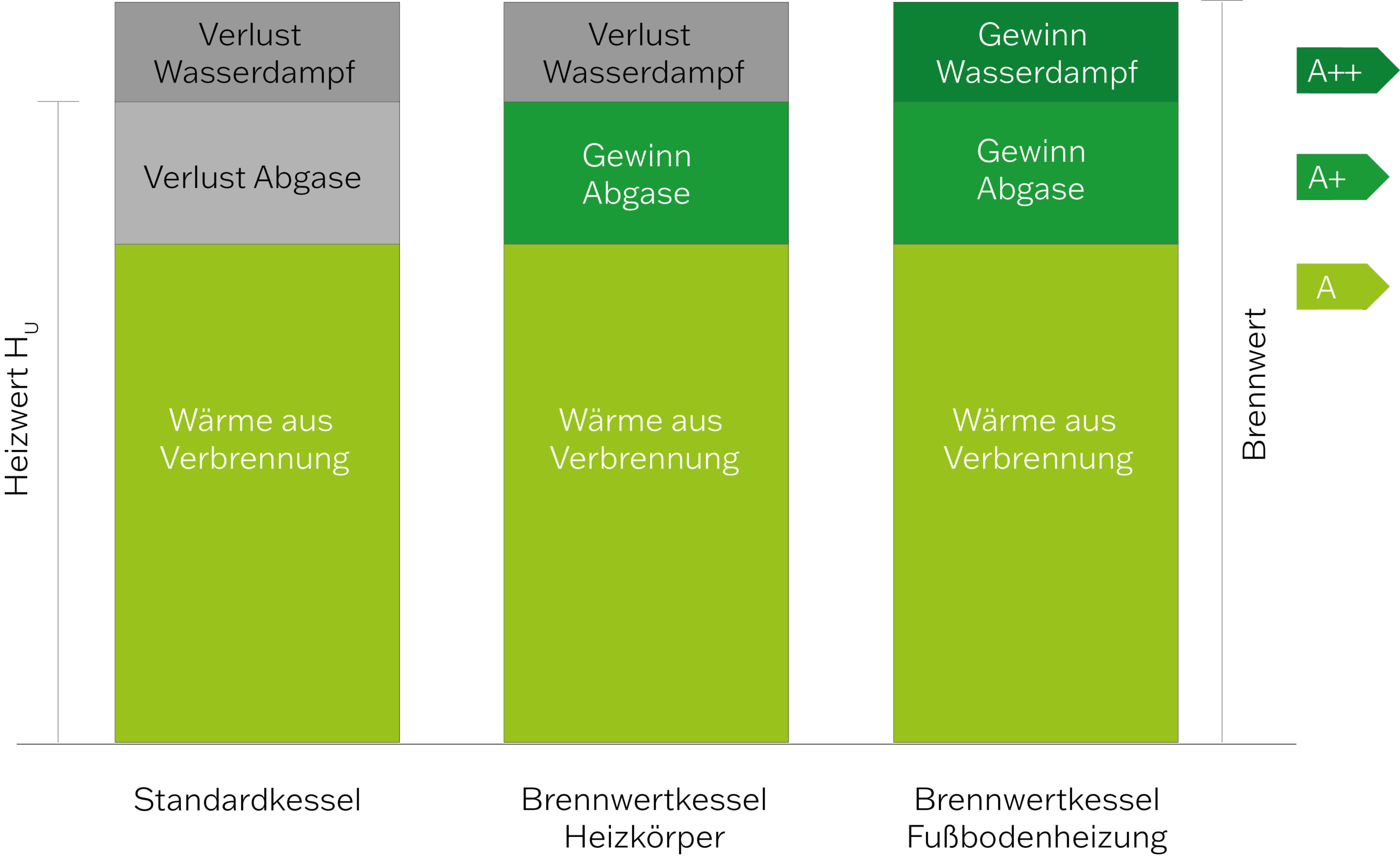

The pellet condensing boiler offers the most efficient way to heat, with the smallest CO₂ footprint. This condensing technology extracts every last bit of heat still contained in the exhaust gases. The water vapor within them is condensed, and the released heat is fed back into the heating system. The efficiency rate is up to 15% higher than that of a conventional pellet boiler.

When combined with surface heating systems such as underfloor heating, exhaust temperatures range between 28 and 38 °C. Emission levels remain well below strict legal limits, without the need for additional separators or filters. Once again, this demonstrates the outstanding combustion quality for which all BRUNNER products are known.

The system comes fully equipped with an integrated boiler pump, expansion vessel, boiler safety unit, and control system for the boiler, heating circuits, domestic hot water, and solar integration.

- 2. Variable output range

The output range automatically adapts to the current heating demand. The continuously variable, speed-controlled fuel feed supplies the system with between 4 and 17 kW.

- 3. Environmentally friendly fuel

Pellets – small compressed pieces of wood – are a remarkable fuel made from a valuable, renewable raw material that burns almost CO₂-neutral.

- 4. Space-saving

With a footprint of only 0.53 m² (0.84 m² including the hot water tank), space issues simply disappear. The boiler output automatically adjusts to the heating demand across a wide range from 4 kW to 17 kW.

With the tested air supply kit, the system can operate independently of indoor air – suitable both for new buildings and for energy-efficient renovations.

With a flue connection from boiler to chimney, the BPH is also available as a non-condensing version with higher exhaust temperatures and can usually be operated without issue on existing chimneys up to 150 mm in diameter. If chimney renovation is required, BRUNNER provides a perfectly matched renovation package in DN 100 mm.

- 5. Simple and intuitive operation

With the touch display, you always have your heating system in view. All functions are shown and controlled centrally. Online access to “my heating” mirrors the familiar display view exactly. Simply register at myBRUNNER and install the app. You can access your system from any internet-enabled device.

A second display with a white or black glass panel can be installed in the living area or entrance. This gives you a quick and convenient overview of your current heating situation at any time.

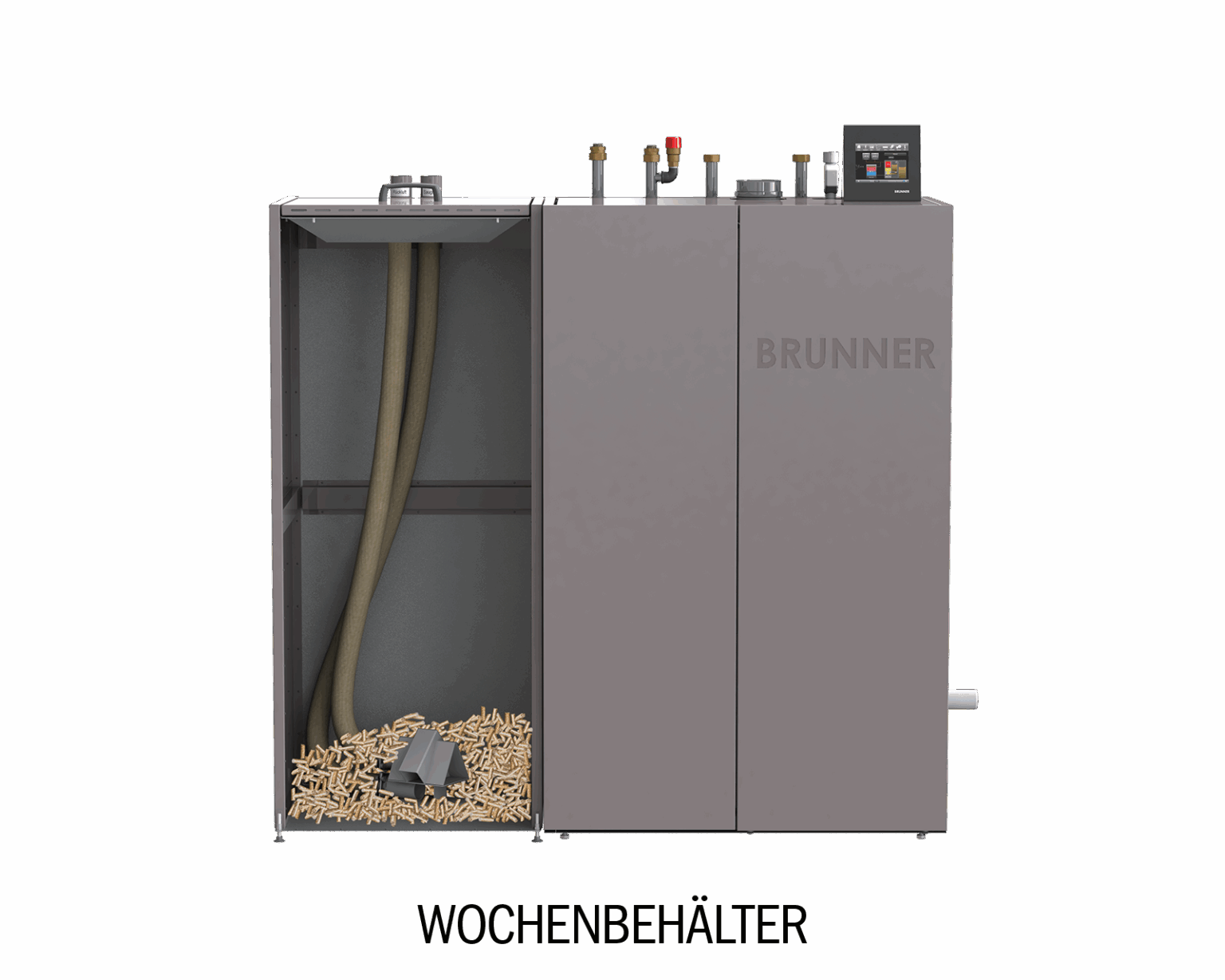

- 6. Pellet container

There’s always room for pellets. Four square meters of floor space are enough – with or without a basement: whether for a weekly container with only 0.36 m² footprint, a bag silo, or a larger pellet storage unit.

In places where a large pellet silo or similar setup isn’t possible, the pellet heating system can be expanded with the weekly container. This allows for convenient refilling with individual bags as needed.

- 7. Quiet operation and low maintenance

Fully automatic, low-maintenance, and quiet – from ignition to ash removal. The ash container only needs to be emptied three to four times a year. All notifications appear automatically on the display.

- 8. Spacious and easy-to-empty ash box

The superior combustion of BRUNNER pellet boilers results in less ash and longer emptying intervals. The spacious ash box is neatly integrated into the heating unit. The external mobile ash container can be conveniently transported like a travel trolley. The casing of BRUNNER pellet boilers can be removed without tools for easy access.

- 9. Ash removal

Runs automatically “Grate ash”

- 10. Pellet feed

Automatic, with integrated suction fan

- 11. Ignition element

Ceramic 300 W

- 12. Wastewater connection

with Siphon

- 13. Return and flow

Heating circuit

- 14. Return and flow hot water storage

or Puffer tank

- 15. Pre-assembled and reliable comfort solutions

A heating system is only as good as the interaction between heat sources and heat consumers. At BRUNNER, all components of log and pellet heating systems are perfectly coordinated in terms of control technology.

- 16. Eligible for subsidies

Take advantage of the opportunity and secure the current subsidy for existing buildings: old heating systems are replaced with modern, low-emission systems that generate heat from renewable energy sources. It’s important that the subsidy application is submitted in advance directly via the BAFA

BAFA website.

The BRUNNER Pellet heater

One of the smallest pellet condensing boilers in the world

The condensing technology of

the BRUNNER pellet heating system

The condensing technology of BRUNNER pellet heating systems can be combined with radiators, underfloor, or wall heating. Especially in low-temperature systems, the return temperature is low enough to trigger condensation of the water vapor in the exhaust gases.

In conventional combustion, exhaust gases escape through the chimney at relatively high temperatures, along with unused water vapor. This residual heat can only be utilized through condensing technology. By further cooling the exhaust gases within the boiler, flue gas losses are minimized and the water vapor condenses in the heat exchanger. The additional heat gained from condensation and the lower exhaust temperature is then fed back into the heating system.

Condensing boilers extract nearly all of the heat contained in the pellet exhaust gases. This additional yield of up to 15% represents the energy savings made possible by condensing technology. The process also naturally purifies the exhaust gases, resulting in emissions well below the limits required by environmental standards such as the “Blue Angel.”

With a condensing boiler, energy costs can be reduced while actively protecting the environment — a contribution further supported by government incentive programs.

- Ideal conditions for operation

- Moisture-resistant chimney (stainless steel or ceramic)

- Low-temperature heating system such as underfloor or wall heating. Systems with return temperatures above 40 °C (e.g. radiators) are technically possible but less efficient.

- Condensate drainage connected to the wastewater system

- Outstanding emission values without secondary measures

- Thanks to low-emission combustion, BRUNNER pellet boilers operate without the need for particle separators or fine dust filters.

- The emission limits of the German BImSchV, Stage 2, are clearly undercut by our pellet heating system – while maintaining top efficiency.

- The patented two-stage high-temperature swirl combustion chamber in the BRUNNER pellet boiler ensures maximum heat transfer.

- Automatic heat exchanger cleaning contributes to consistently high boiler efficiency.

The combination with with the BRUNNER heating center

In combination with the BRUNNER heating center, the BPH can be expanded and combined in a variety of ways: domestic hot water production via a fresh water station, additional heating circuits, or the use of surplus solar power through PV integration.

And all of this is managed through a single control unit and a unified user interface. With just one look at the glass touch display, you can see all key parameters, from boiler status to buffer temperatures. The clear and intuitive layout makes operation of the entire heating system self-explanatory.

Good to know

The BPH is the only pellet boiler on the market with continuously adjustable fuel feed and combustion control via a lambda sensor and differential pressure transmitter for precise air flow measurement. This technology compensates completely for variations in fuel quality, air supply, flue conditions, and ambient environment. The excellent use of condensing energy is maintained even during buffer operation, with a temperature spread of up to 50 K between flow and return.

A return temperature boost is not required. Thanks to its low water content and optimized ignition strategy, the boiler responds quickly to heat demand. The loading pump and expansion vessel are integrated into the unit. Operation directly on heating circuits and hot water tanks is possible even without a buffer tank. A 200-liter hot water storage tank is also available.

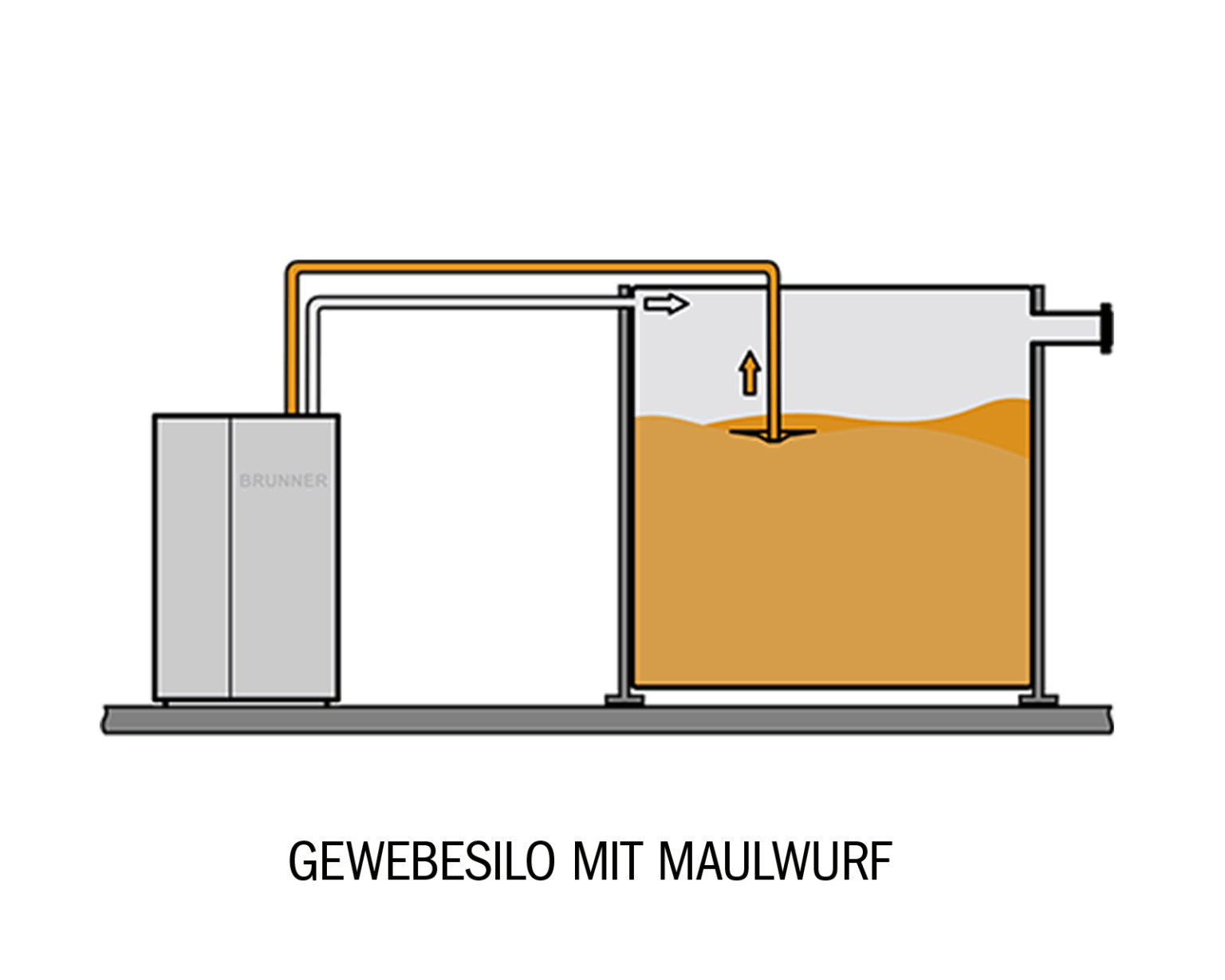

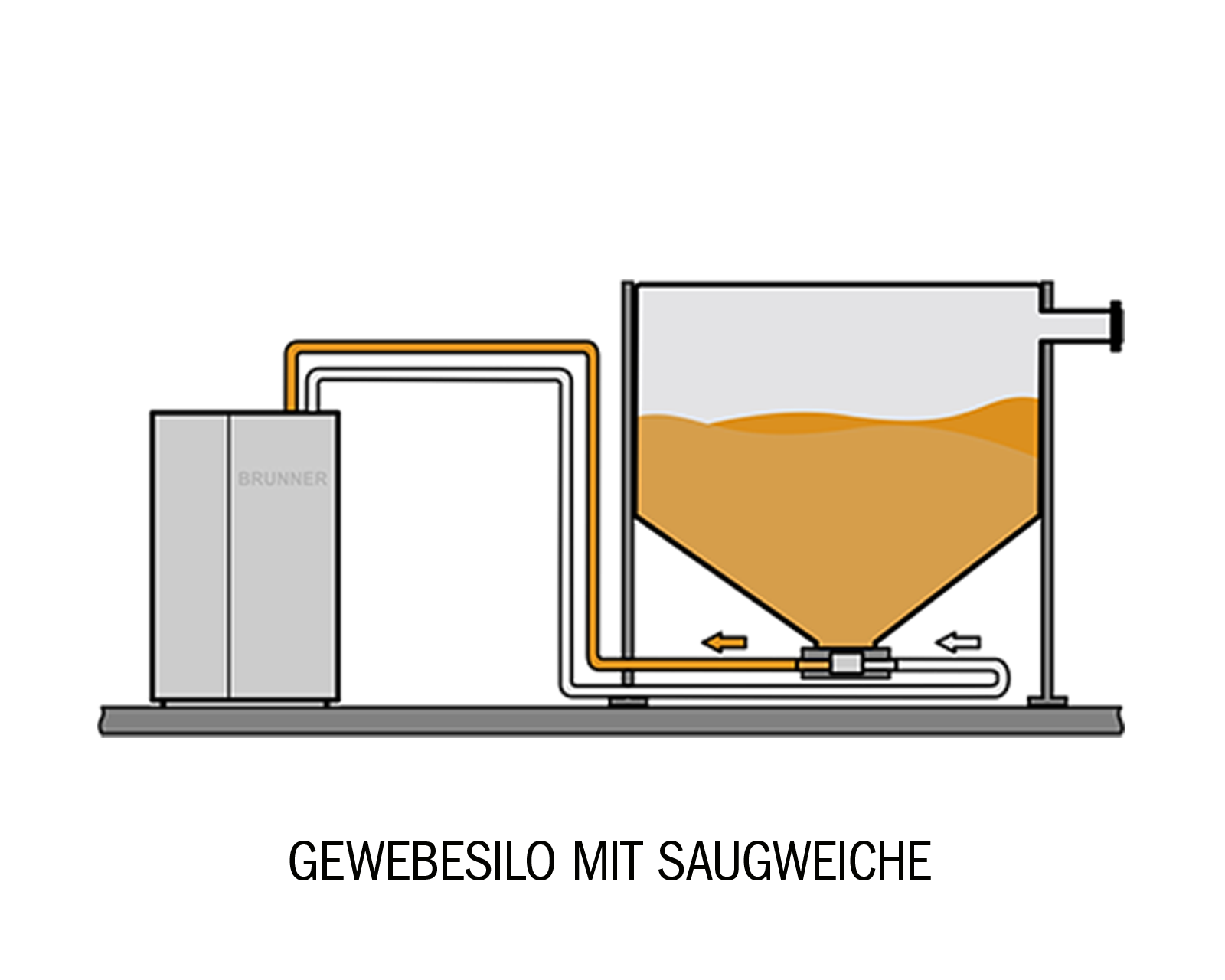

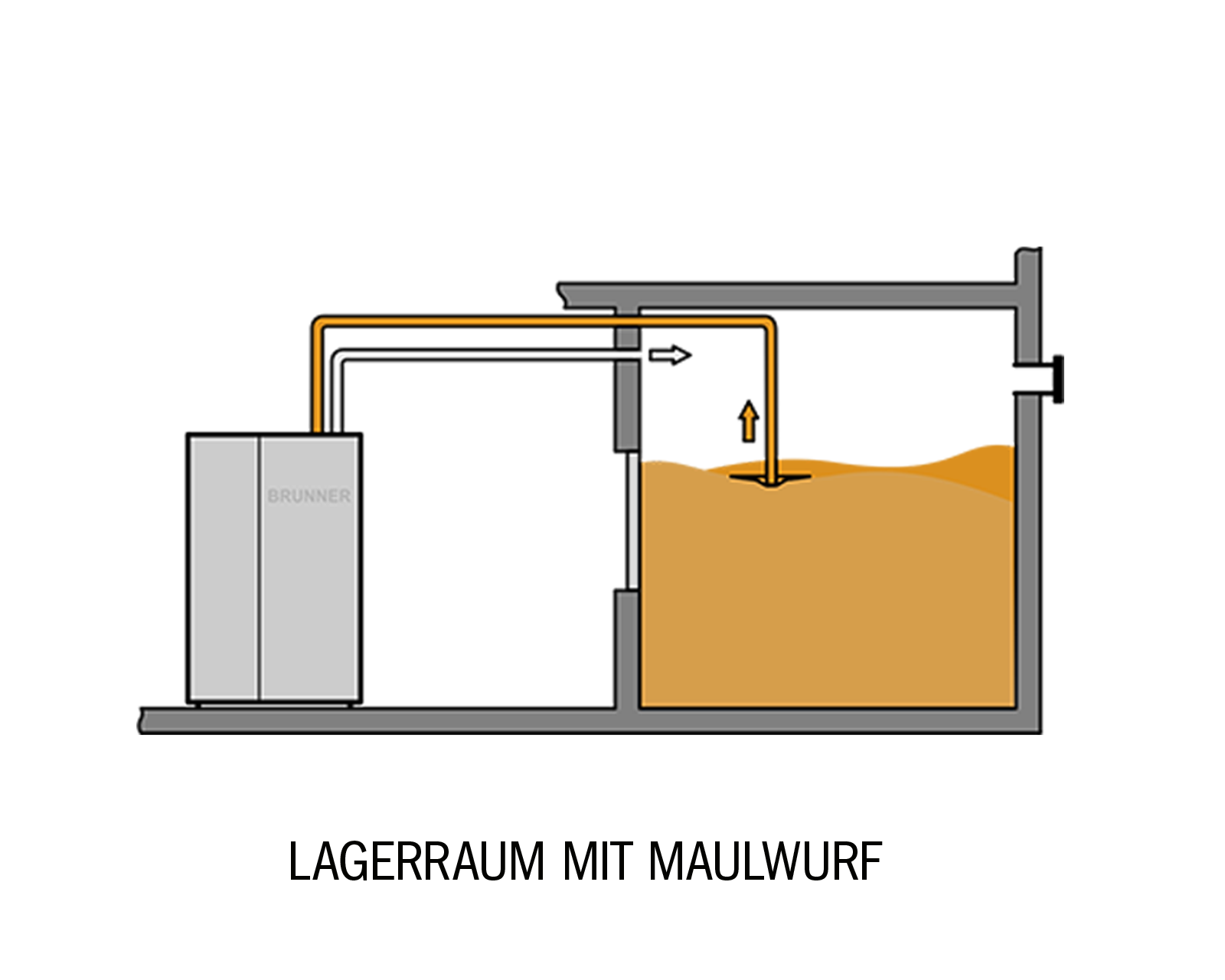

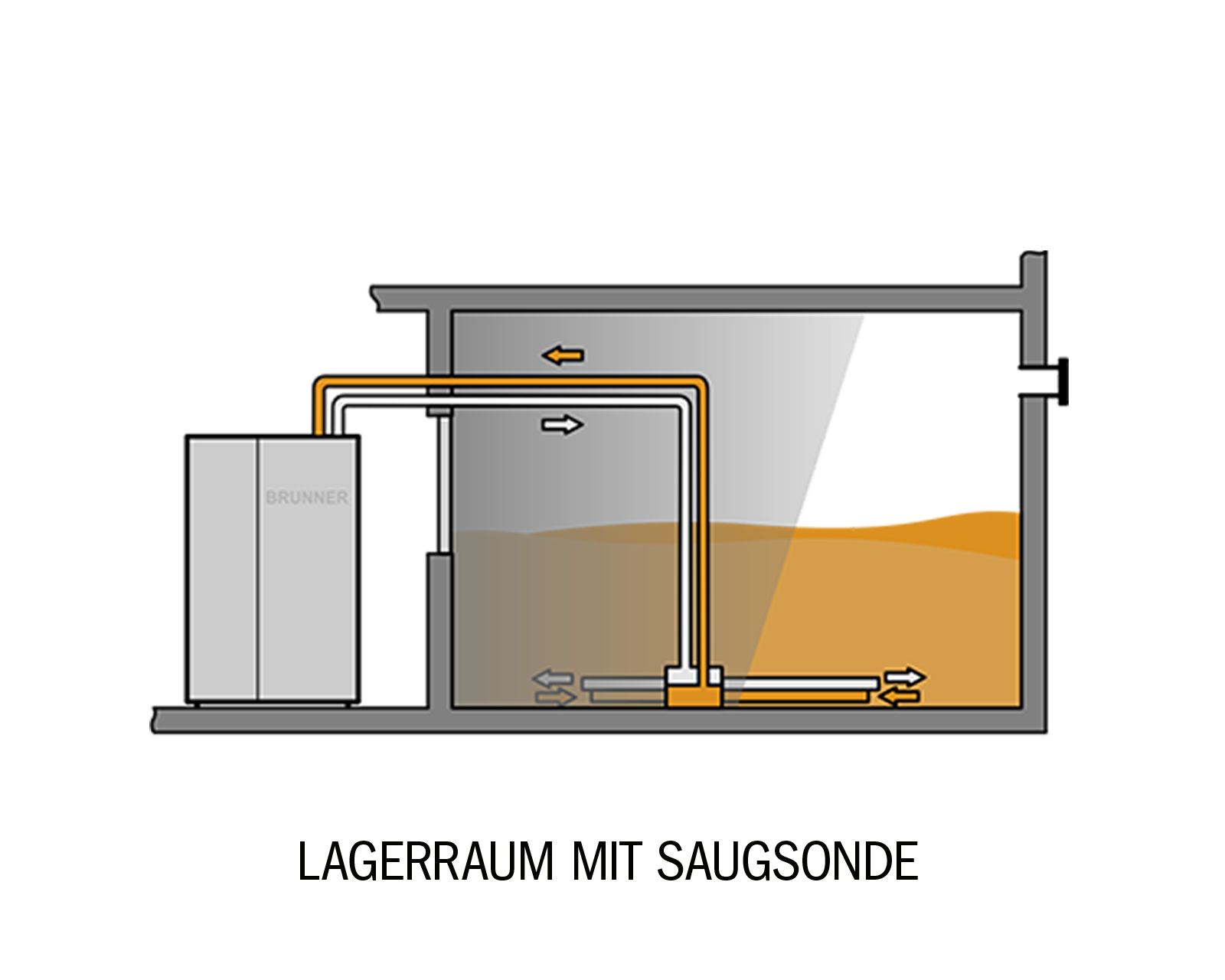

Pellet extraction systems – safe and dust-free

The annual demand determines the size of the pellet storage unit

The pellet storage should be sized to hold the full annual requirement of pellets. Depending on the building’s heating demand – or based on previous oil consumption – the necessary pellet quantity and thus the storage size can be calculated. For example, around 2 tons of pellets correspond to roughly 1,000 liters of heating oil, which equals a heat demand of about 8,000 kWh per year. Thanks to efficient use of space and professional connection points for gentle loading and extraction, prefabricated storage systems are used for both indoor and outdoor installations.

No space for a silo?

Choose the smallest “pellet storage” option: the manually filled weekly container. This is the ideal alternative when refilling is needed only every one to two weeks, as in new buildings. Pellets are supplied in 15 kg bags and can be stored easily. The BRUNNER weekly container holds up to 300 kg of wood pellets, which are automatically drawn from below by a suction probe.

Compact and expandable

- The entire heating system requires no more than one square meter of floor space.

- A robust design allows easy transport with a stair or sack trolley.

- Expandable with a 200-liter hot water tank.

- Manual-fill storage container – perfect for switching to pellets quickly or as an alternative to a full-year silo.

The different Heating solutions

Compact

The heating solution with the smallest space requirement. Everything a modern heating system in a single-family home needs – all on just one square meter of floor space. The most compact option when replacing an existing oil heating system.

- Condensing technology for direct connection to two heating circuits including domestic hot water.

- Compatible 200-liter hot water tank (BWS 200).

- Existing hot water tanks, with or without a solar thermal system, can continue to be used and integrated into the control system.

- Optional photovoltaic integration for hot water production.

Comfort

The flexible and comfortable solution for renovation and new construction, featuring a 750-liter buffer tank for heating, domestic hot water, and solar integration (photovoltaics and solar thermal).

- Condensing or non-condensing technology.

- 750-liter heating water storage tank with integrated heat exchangers for domestic hot water and solar thermal.

- On-demand hot water generation based on the flow-through principle using a coil heat exchanger.

- Optional photovoltaic and solar thermal integration for heating and hot water (with solar thermal, the second heating circuit is not required in the control system).

Plus

Everything is possible. A well-engineered, preassembled heating system that accommodates even complex configurations with multiple heat sources — and works reliably. Ideal for multi-family homes, duplexes, new builds with separate apartments, and demanding heating setups with various heat generators.

- Condensing or non-condensing technology.

- Stratified storage tank with capacities of 750, 1000, 1500, or 2000 liters.

- Preassembled hydraulic box for multiple heat sources and consumers.

- On-demand domestic hot water generation using a plate heat exchanger.

- Optional photovoltaic and solar thermal integration for heating and hot water.